Michigan Scientific Corp (MSC) has had an astounding year for the Wheel Force Transducer (WFT) product line. WFTs are an ideal tool for measuring the three forces and three moments on a large variety of vehicles. We have made many advancements in the design and manufacturing of WFTs, culminating in multiple success stories for customers new and old throughout the world. With 2018 in the rear-view mirror, we are excited to see what the new year brings for our biggest product line. Let’s take a look back at the past year and review all of the advancements we have made with the Wheel Force Transducer.

You Asked, We Listened

Customer satisfaction takes priority at Michigan Scientific. We strive to make a product that gives us pride and satisfies our wide variety of customers. An integral part of maintaining customer satisfaction is listening to customer desires for future instrumentation and applications. Without our wonderful customers, we would just be a warehouse full of unused transducers.

Here are just a few of our notable improvements from 2018:

ISO 9001 Certification

Quick Transducer Calibration

With the development of the patented transducer calibration machine, WFT calibration time has significantly decreased, allowing for a faster turnaround and return to customer. The calibration process is now also automated, which allows our highly skilled technicians to focus on transducer design and manufacturing improvements.

Stator Angle Corrector

The SAC makes WFT set-up even quicker and easier, eliminating the need for over-the-wheel brackets on front-steered vehicle wheels. It provides superior accuracy for position reference during any type of testing that requires a Wheel Force Transducer. The SAC adjusts the real-time rotational angle signal from the wheel, which is used for the coordinate transformation to prevent error while the wheels are steered during dynamic testing. This provides quick and accurate measurement results while eradicating tedious post-processing compensation of the data.

Success and Versatility

We love getting feedback from our customers and we’re proud to service a wide variety of vehicle manufacturers.

The Future is Here – Electric Vehicles & Autonomous Vehicles

With concerns over the environment and rising gas prices, more and more manufacturers are turning their attention to the advancement of electric vehicles. These advancements have historically focused mainly on smaller cars however, since demand is increasing other companies have been able to work on developing electric trucks and SUVs, such as our friends at Bollinger. No matter what type of electric vehicle is being developed, accurate and reliable testing methods are always crucial. These testing methods may require slip ring solutions for internal engine components, or Wheel Force Transducers for outboard measurements on electric vehicle wheels. Bollinger used our Wheel Force Transducers for durability testing for their suspension development. Durability testing is a critical component to the design and validation of a vehicle and the components. It is used to determine the expected life, as well as improve design. Check out the video below to see MSC Wheel Force Transducers in action:

Wheel Force Transducers are also a great tool for autonomous vehicles. This futuristic means of transportation is already being used today. Autonomous vehicles are often gracing our roadways for testing and validation as well as for road mapping for GPS verification. Another great tool for this application is the Michigan Scientific Wheel Speed Sensor. This instrumentation is necessary for the advancement of transportation technology and Michigan Scientific is excited to create custom solutions for these innovative companies.

Widest Capacity Range – Heavy Duty Trucks to Motorcycles

Each of these different models can be used in conjunction with road simulators. This provides an opportunity to produce real-world results for durability and dynamic testing, in a controlled laboratory setting. Engineers can use the information collected from the simulators to determine the necessary modifications to the vehicle design. From compact vehicles to large tractors, Michigan Scientific WFTs have been used for a variety of simulator applications.

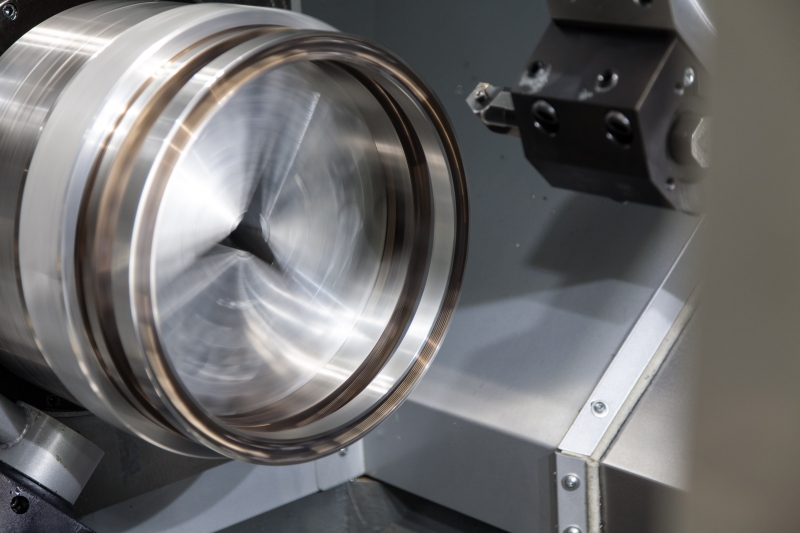

In addition to producing a large range of high quality transducers, we also design and manufacture custom rim and hub adapters, or we can provide guidance for customer manufacturing at no cost. Lightweight rim adapters are machined from aluminum forgings. Standard rim adapters are modified, welded, production rims. Lightweight hub adapters are machined from 6A1-4V Titanium, which greatly reduces added weight to the wheel. Standard hub adapters are fabricated from high strength stainless steel.

What is Next?

While we continue to make many advancements with the product, we are also spending some of 2019 focusing on our own manufacturing processes in the hopes of continuing to reduce lead-time and increase capacity. This is a key component to customer satisfaction, and one aspect that can continually be improved.

With all of our exciting advancements in 2018, and more to come in 2019, we are excited to work with you on your next vehicle testing project. Please contact a Michigan Scientific representative to begin discussing your application.