When it comes to innovation, Michigan Scientific Corporation (MSC) is always at the forefront of cutting-edge vehicle design and testing. With a new ISO 9001 certification, MSC Wheel Force Transducers (WFT) are used in a variety of testing applications on many different types of vehicles. From heavy duty trucks, to small and agile ATV’s, the MSC WFT is the first choice in specialized testing and measurement applications, such as rigorous durability testing.

What is Durability Testing?

Durability testing is a crucial component to the design and validation of a vehicle and the components. It is used to determine the expected life, as well as improve design. Wheel Force Transducers are an integral part of durability testing. Michigan Scientific designs and manufactures durable and reliable transducers that can be used in any environment, on the proving ground or in the lab. They provide all wheel force and moment data along with acceleration, wheel speed, and wheel position, which can be used for validation or to improve future vehicle configuration. A video of MSC Wheel Force Transducers being used during durability testing for electric vehicle development is shown below:

Not only are WFTs an essential tool on the track, they are often used for public road durability testing, providing real environmental results. One aspect of public road durability testing is measuring the response from a vehicle when it drives over a pothole.

Pothole Case Study

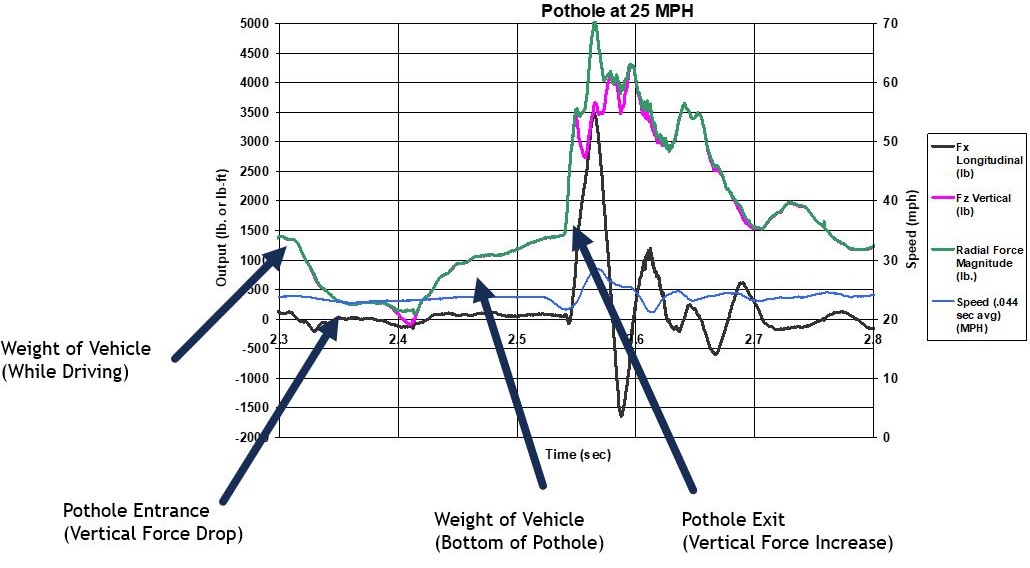

Shown below is actual data from a pothole test. This graph displays data gathered during an event in which an SUV’s right front wheel hit a pothole at 25 miles per hour (MPH).

This is a typical output that one may see during pothole testing. Since this is a real environment application, the event happens very quickly, at under 0.5 seconds. The weight of the vehicle is just under 1500 lbs, shown in the beginning of the data in the green Radial Force Magnitude, with the Fz Vertical Force underneath. The vertical force then drops when the wheel enters the pothole and is free falling. Upon making contact with the bottom of the of the pothole, the force returns to the approximate weight of the vehicle, just under 1500 lbs. The largest event happens when the wheel exits the pothole. There is a large increase in the force as the wheel comes in contact with the edge of the the pothole. As the vehicle suspension system responds to the impact of the pothole, the force fluctuates, until it returns to vehicle weight towards the end of the data set.

A pothole test is just one of a multitude of different tests that utilize Wheel Force Transducers. Having a durable and accurate measurement system is crucial for studying how a vehicle responds to various road conditions. If you are would like to discuss your wheel testing application, contact a Michigan Scientific representative today.