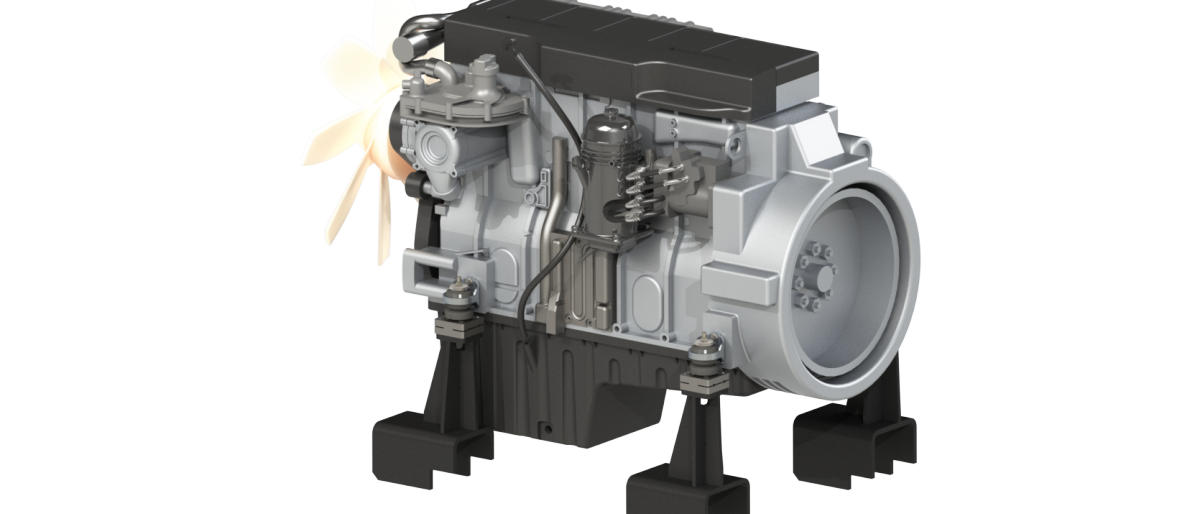

Michigan Scientific (MSC) offers innovative, precise, and diverse testing solutions, meaning there are suitable MSC testing products for every application. The load cell is one product frequently used in industrial applications that require the measurement of forces and moments. Michigan Scientific offers one, three, five, and six axis transducers. Multi-directional load cells produce optimum results when measuring dynamic forces in an engine mount during critical maneuvers.

Why Test Forces in an Engine Mount with a TR3D?

Load cells have a rugged, compact design that makes them suitable for a wide range of testing applications.

Michigan Scientific’s TR3D Load Cells are compact, three directional load cells that measure forces in longitudinal (Fx), vertical (Fz), and lateral (Fy) directions, making them perfect for installation in a vehicle engine mount. Testing forces in an engine mount with a TR3D reveals the loads imparted on a vehicle frame during hard maneuvers. Comparing this real-life data with expected results is an important step in sound vehicle development. Areas of the engine mount that repeatedly experience large forces acting against them may need to be strengthened or redesigned.

Engine Mount Forces Case Study

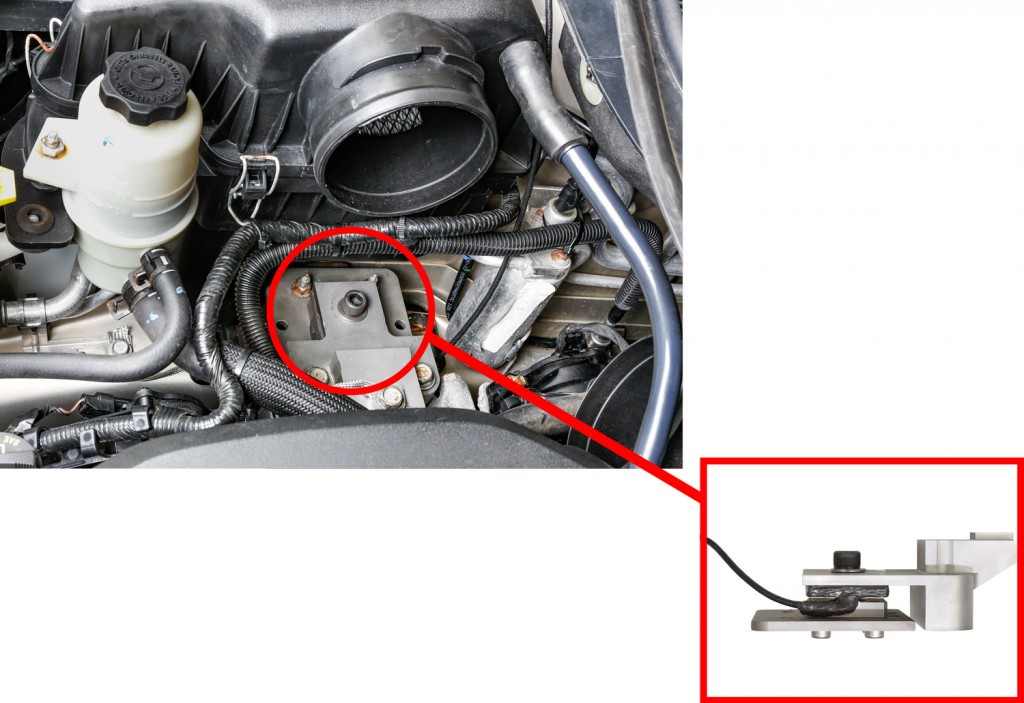

Shown below is actual data from a test where a TR3D-B-4K load cell was installed inside the engine mount of a van.

Set Up

An adapter was designed to replace the engine mount and direct the reaction forces through a TR3D load cell. The model TR3D-B-4K, 4,000 lb capacity load cell was installed in the engine mount adapter. The adapter was then installed on the engine in place of the original production engine mount.

In this test, a TR3D load cell was installed on an adapter (bottom right) which then replaced the engine mount inside the vehicle (top left).

Data Analysis

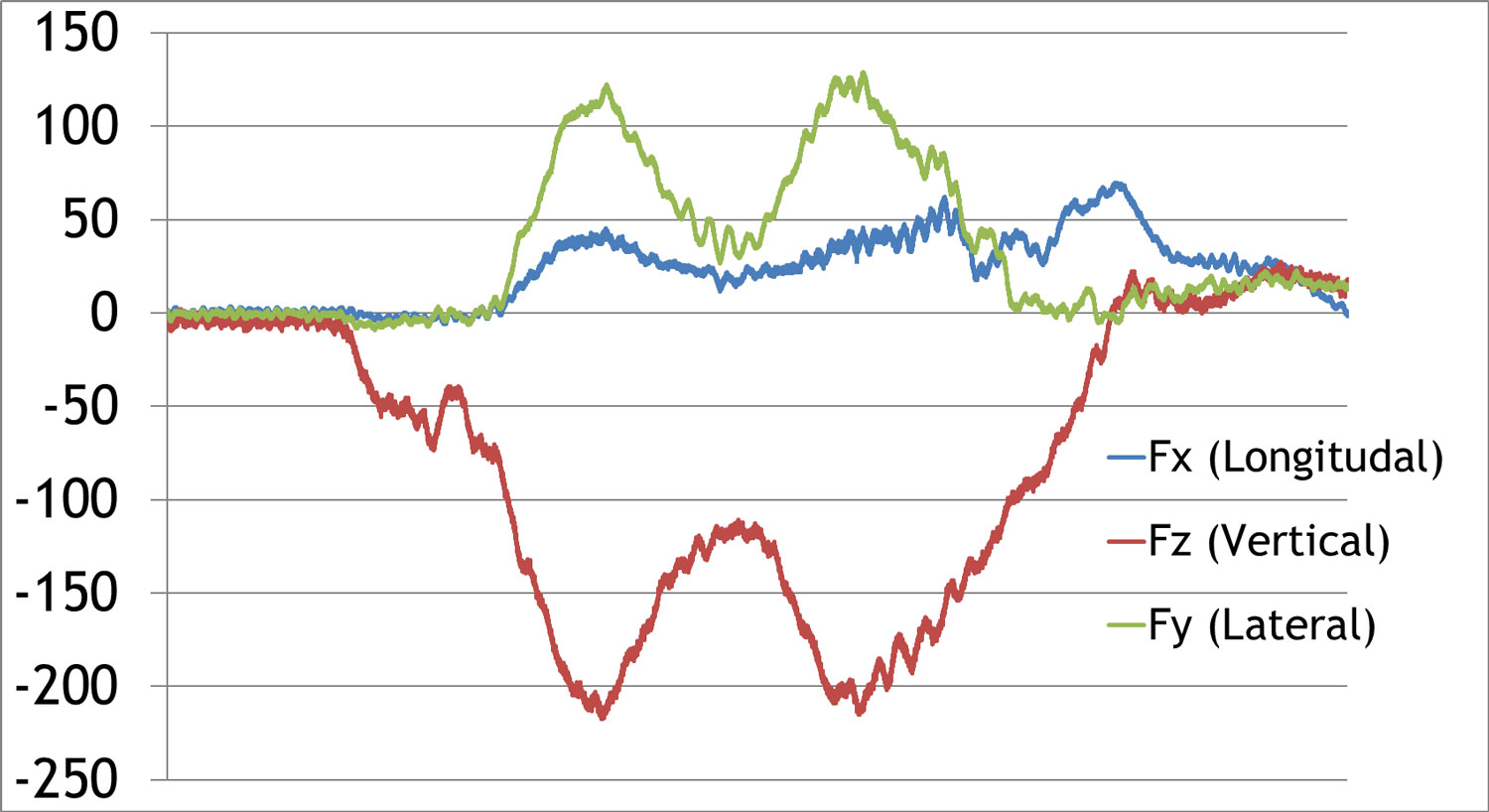

The test involved the van starting at rest before suddenly and fully accelerating. The sharp changes in the graphed vertical and lateral force data were caused by engine torque as the van accelerated. The dips in acceleration force are where the transmission shifted gears. The engine mount in this test experienced over 200 lbs (90.7 kg) of vertical force in addition to the static weight of the engine. Note that the static loads were “zeroed” before the test began, so that the output was equivalent to only the change in force during testing, not including the engine weight.

Force Output From a TR3D-B-4K Load Cell During Engine Mount Testing

This graph of the data in from the TR3D shows the force response from a van’s acceleration from a complete stop, in lbf.

Engine mount measurements are just one use for the multi-directional load cells. Having a durable and accurate measurement system is crucial for studying how a machine responds to various conditions. If you would like to discuss your industry testing application, contact a Michigan Scientific representative today.