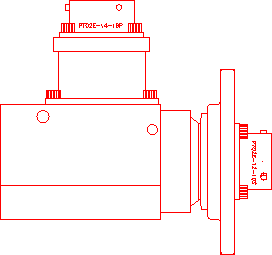

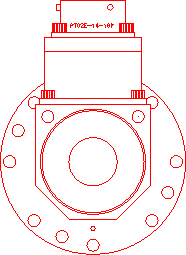

The SR10A_/AX Slip Ring Assembly has 10 slip ring circuits and a Type A (2.500″ diameter) rotor.

Features

- 10 slip ring connections

- Available with or without weatherproof seals

- Type A (2.500″ diameter) rotor

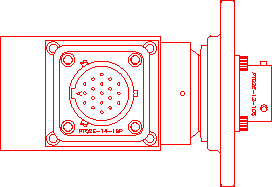

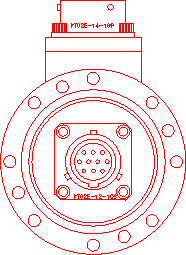

- Circular connectors on stator and rotor

- Instrumentation quality rings & brushes

- Sealed, corrosion resistant metal housing

- Lightweight and compact

Description

The SR/ERT Series is used when a slip ring needs to be mounted at the end of a rotating shaft. The gold alloy slip rings are used to make high quality electrical connection to strain gages, thermocouples, or other sensors that have been installed on rotating machinery. Current capacity is 0.5A per connection and the maximum peak resistance variation is 0.1 ohm. The SR10A_/AX does not have an integrated encoder, but is a standard slip ring interface in an ERT housing. These are commonly used because of their connector orientation.

The housings are approximately three inches long. They weigh about 15 ounces. The rotors are made from high strength stainless steel. The stators are lightweight, nickel-plated, aluminum. Threaded holes are provided for attaching a rotation restraint. Connection information is permanently engraved on the housing. Circular connectors or solder terminals are offered as wiring terminations.

All housings in this series have been designed to accept contacting rotary seals. Units ordered with these seals (choice W) are completely weatherproof and can survive days of total submersion. The seals limit operation to 2000 rpm maximum. Most wet weather applications, like automotive wheels, are within this range. For higher speeds in dry conditions, order units without the contacting rotary seals. Units without seals are capable of the following speeds:

- 10 rings – 10,000 rpm

Unit torque with seals is 21 inch-ounces. Unit torque without seals is three inch-ounces.

Videos

Documents

Please note that the SR10A/AX has the same dimensions as the SR10A/E___/AX

Tech Notes

Last Modified: