Features

- 6 circuit weatherproof slip ring

- Compact design

- Mounts on shafts up to 3.2″ [81.3 mm] in diameter

- Permanently lubricated bearings

- Rugged stainless steel construction

- Instrumentation quality rings and brushes

- Optional 60 pulse per revolution encoder package that produces a square wave voltage output

Description

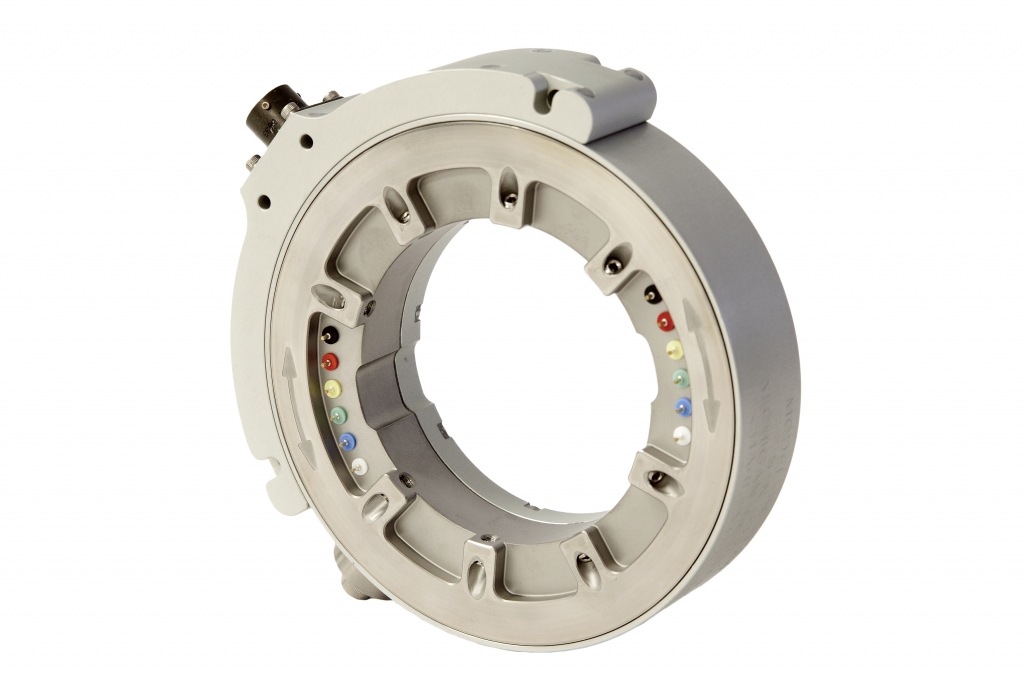

Michigan Scientific’s B6-3.2W Weatherproof Slip Ring Assembly is ideal for applications that require the slip ring to be sealed and mounted directly on a rotating shaft. Typically used for automotive drive shaft measurement applications, this model employs specially designed seals that provide weatherproof protection from water, mud, snow, dust, and other contaminants. It is designed to fit on shafts up to 3.2” in diameter and make electrical connections to strain gages, thermocouples, or other sensors that have been installed on rotating equipment. The slip ring brushes and rings are made of precious metals which minimize noise and enable the assemblies to be used for low level instrumentation signals.

The six circuit capacity of this slip ring allows for more than one full bridge strain gage measurement channel. This is particularly useful for drive shaft applications where both torque and axial measurements are needed. In addition, the B6-3.2W provides enough circuit connections for use with spinning amplifiers. Locating precision amplifiers on the rotating side of the slip ring greatly improves signal quality because the amplifier is located closer to the sensor. This reduces errors due to long lead wires, connector resistance variations, electro-magnetic interference, and temperature gradients across slip ring contacts.

This assembly is available with an optional encoder package. The B6-3.2W/E60 produces a 20 pulse/revolution square wave voltage output. The signal is produced by a hall effect sensor, which allows the speed to be determined down to zero rotations per minute.

Connections are made through color coded solder terminals located on the slip ring rotor, and a connector on the slip ring stator. The compact design of these slip rings make them ideal for applications where limited space is available.

Documents

Tech Notes

Last Modified: